Cuyuna engine, Cuyuna aircraft engine - Cuyuna engine troubleshooting report. |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

| Cuyuna aircraft engine problem solving. | |||||||||||||||||||||||||||||||||||||||||||||||

|

Troubleshooting the

Cuyuna 430R ultralight aircraft engine. Part of the growth of the ultralight industry can be attributed to the availability of light weight but powerful two stroke engines. One such engine was the Cuyuna 430 R. In its hay day the Cuyuna was used by most of the leading manufacturers. It was cheap, powerful, yet relatively small in size. Many ultralight pilots swore by its reliability, others simply swore at it. For, while one engine might run for hundreds of hours without a problem, others had difficulty running for a hundred minutes. Today little is heard of the Cuyuna although it is again being produced, and parts are readily available. It is still being used widely on older ultralight aircraft, and on aircraft that were purchased prior to the influx of Rotax engines. Some owners of high time built kits such as the Bobcat, Hovey Delta, etc, are just now installing these engines on their newly completed projects. In an effort to aid these pilots the following is a synopsis of some of the problems encountered with the Cuyuna 430 R, and their possible solutions. The problems cover several areas. FUEL SUPPLY:

EXHAUST SYSTEMS :

ENGINE COOLING:

The Mikuni fuel pump is the primary pump used in the ultralight industry, and with the Cuyuna engine. When mounting the pump make sure that it is no more than 11 inches away from the impulse outlet on the engine. Make sure that it is mounted away from any heat source, and that it is positioned so that the vent on the pump face is facing down. The vacuum line used to connect the pump to the engine impulse outlet is of a much thicker wall thickness than regular gas line, and is not effected by heat. The gas line and vacuum lines are generally exposed to sunlight in most older configuration of ultralights and it is suggested that they be checked on a regular basis for cracks, discolouring, or UV deterioration. All lines should be carefully clamped, with clamps that do not pinch the line. The fuel system should have some kind of a water trap, this can be as simple as a loop in the line used to join the two gas tank halves together on a root tube mounted tank, a proper inline filter with a drain cock, or a pickup line located an inch from the bottom of the tank. tank. During initial installation of the tank it should be inspected to make sure that no plastic is present, inside, from the drilling of holes, or from the manufacturing process. More than one pilot has had to land with an engine out only to discover plastic lodged in his fuel pump. A fuel filter should be installed in the fuel system prior to the pump to prevent any foreign material from entering it. If for any reason the filter is removed and is going to be reused make sure that the direction of flow is the same as when it was removed. Several pilot has reported reinstalling their fuel filter backwards, depositing all the foreign material collected directly into their pump and carburetor. Most quality filters have arrows showing the direction of fuel flow. When considering fuel tank location, try to make it as close to the engine as possible with the least amount of vertical draw. Although the Mikuni pump has been known to draw fuel vertically over 4 feet the recommended distance is only 18 to 24". If your aircraft is equipped with a Cuyuna engine, and you are considering using an extra fuel tank, it is possible on the Cuyuna to run two fuel pumps, as it has two impulse outlets. It is suggested that you use this second pump to pump the fuel from your storage tank, or seat tank into the main tank. A simple shut off valve can be installed in the line to prevent overfilling. Make sure all tanks are properly vented. Many ultralight manufacturers use a standard marine fuel tank, with a vent on the handle that can be screwed in to seal for transportation. The problem here is that the vent can vibrate closed, or can be inadvertently left closed. This allows the engine to run for a short period of time before it runs out of gas, just about the time your 50 feet in the air. If you have one of these tanks a solution is to drill a small hole in the handle, at its highest point. Another problem with some of these tanks is that they have a steel check valve located in the tank fuel outlet, in some cases this ball is to heavy for the Mikuni fuel pump to lift completely, causing a fuel starvation problem. Make as few restriction in your fuel system as possible. Some pilots have installed electric fuel pumps into their systems, in addition to the Mikuni pump. There are several potential problems with this. First the electric pump is capable of producing considerably more pressure than what the fuel system is set up for. Secondly when the pump is turned off it is an added restriction. In most applications the Cuyuna engine uses a 32mm Mikuni carburetor. In adapting the Mikuni for ultralight use several problems were encountered. The first and most widely reported was the failure of the retaining clip of the jet needle, due to vibration and fatigue located in the carb slide. This failure allows the jet needle to fall down into the main jet cutting of the supply of fuel to the engine. The engine still runs but at an idle. This should be an area of regular inspection. An update kit was available at one time which replaced the slide and jet needle, and allowed for the placement of a small plastic spacer between the slide and clip helping to eliminate wear and fatigue on the clip. Another area of reported wear is in the two towers used to support the float arm hinge. Wear has been found in the area of the tower where the pin goes through. Another area of concern is the float itself. The two floats used on most of the ultralight equipped Mikuni carbs are hollow. More than one owner has reported leakage in one of the floats, generally around the hollow brass guide, allowing it to sink rather than float. Although this does not generally effect the engine at an idle in calm conditions, it plays havoc with the fuel mixture in rough conditions. As the one float cannot supply enough buoyancy to counteract the turbulent conditions. There are two vent tubes located on the side of the Mikuni carb, these tubes are meant to point DOWN, and are suppose to vent excess fuel. Do not connect any additional hoses to these vents, or vent them outside an enclosed engine installation. By doing so you could create a siphoning effect when they do vent, and by venting outside the engine cowling you create two different air pressure areas, that of the outside air, and that of the air inside the engine cowling, which can effect you fuel mixture. Between the engine cylinder and the intake manifold are found two black bakelight blocks. More than one ultralight pilot has found on preflight engine inspection that the blocks have cracked. If not replaced pieces have been known to break off, allowing for a lean engine mixture, and possible engine seizure. Also it has been reported that pieces of the blocks have entered the engine causing damage. Joining the carburetor to the intake manifold is a rubber intake manifold adapter. Two problem areas have been reported with this rubber intake manifold. The first area is that directly under the clamp used to tighten the rubber manifold to the carb body. It is difficult to locate, since the pilot must remove the carb, and clamp to inspect the area. What has been found is separation or tearing of the rubber. This generally causes erratic running, hard starting, and possible engine failure caused by the leaning of the mixture. The other area of separation is located around the bolt holes used to connect the rubber flange to the intake manifold. Although his area is easier to inspect, it still must be looked at very closely to find the separation. This separation has been reported to be caused by fuel additives, an additional factor is the lack of support for the carb body and breather. In most applications these are all supported by this rubber intake manifold. To help eliminate this problem it is suggested that some way of supporting the carb/breather be found, and that the pilot use premium unleaded fuel. The type of aircleaner used on the Cuyuna engine greatly effects its performance. In fact the engine will not run properly with some air filters. Many pilots have reported being unable to develop full power after installing the ROTAX AIR BOX silencer kit. This kit when used on the Rotax engine requires the rejetting of the engine to accommodate for the added air restriction, to my knowledge no rejetting specification are available for the use of this air box on the Cuyuna engine. Several ultralight manufacturers shipped their kits out using a sponge air filter. This filter is not recommended for most ultralight applications as it is prone to absorb water, especially during early morning, or after rain. Most current manufacturers are recommending the use of the K& N filter. Several exhaust systems were used by different manufacturers with the Cuyuna engine. The first was a motorcycle style expansion chamber. This system proved to cause engine failure quite quickly in most applications when run at cruise settings. The second was an exhaust called the Protopipe, it generally failed after several hours, with the exhaust baffles coming out the back of the pipe and into the prop. For the systems that lasted a little longer, the head pipe generally cracked at the elbow, or where it entered the exhaust body, then fell into the prop. The third system was the Fisher exhaust. This exhaust while a little noisy proved to be a better system. It did require the rejecting of the carburetor. (See accompanying chart.) The forth system was put out by a company in Toronto Ontario called the ACS exhaust. It was also sold under the brand name of Cuyuna. This system proved to be the most reliable and quietest used, and was the system most widely recommended by the factory.

In the area of ignition several problems on the Cuyuna have been reported. The first is the use of the wrong ignition switch on Cuyuna engines equipped with CD ignition. The use of the wrong ignition switch generally results in the blowing of the CDs main output box. The switch used on most Rotax engines and on the Bosch points and condenser equipped Cuyuna is the IMPROPER SWITCH. Another problem encountered is in the use of a shroud enclosed spark plug cap. Pressure exerted by this cap at the base of the spark plug has been reported to cause the cap to be forced off the spark plug resulting in loss of spark to that cylinder. In other cases the screw on cap on top of the plug has become unscrewed allowing the cap to fall off, again resulting in loss of spark. A possible solution is to use a spark plug cap which does not require the use of the screw on cap on the top of the spark plug, and the use of a cap that will not pop off because of pressure exerted at the base. MAGNETO UPDATE Some Cuyuna owners have reported hard starting on their engines. A timing update was issue by the factory. This update involved the REMOVAL OF THE TIMING ADVANCE ARM SPRING , and the resetting of the ignition timing to .070 to .078 before TDC. This spring can be removed without the need to remove the flywheel if done CAREFULLY. ENGINE COOLING: The most widely reported problem with the Cuyuna 430 R was that of seizure caused by overheating. The 430 Cuyuna uses two pulley halves located on the front of the magneto, directly underneath the recoil starter to drive and tension the fan belt. These two halves have been reported to fail from less than 2

hours of use to over 200 hours

If the pulley halves are not replaced at the first sign of cracking then the pulley half simply disintegrates, cutting the fan belt. This intern causes over heating of the engine and seizure. It is suggested that this area be checked on a regular basis, and

if any signs of cracking are discovered that the pulley halves be replaced immediately.

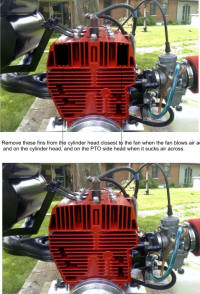

Owners of the old cylinder heads can do this update themselves by simply cutting the cylinder head cooling fins as shown in the accompanying photographs. Another way heat in the engine was minimized was in the use of DOUBLE HEAD GASKETS, A ND THICK CYLINDER BASE GASKETS. This did decrease performance slightly but in some cases was the only solution for some of the Cuyuna engines. Spark plugs were also used in reducing heat in the Cuyuna engine. By running a COLDER range of spark plug temperatures could be reduced. The recommended plug for heavy duty use was the NGK BR9ES. Spark plug gap on points and condenser .016 .019 Spark plug gap on CDI .035 .040 Hope this information can be of some use. Carb jetting exhaust system chart for Cuyuna 430 R using 32MM Mikuni VM carb.

MAIN JET SIZE BASED ON 68 DEGREE F TEMPERATURE AT SEA*LEVEL |

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||

Ultralight

Aircraft News Magazine |

|

||||||||||||||||||||||||||||||||||||||||||||||

|

Ultralight Aircraft News Web Magazine.

You may link to these pages or print

them out for your own personal use, but no part of this

publication may be copied or distributed, transmitted, transcribed,

stored in a retrieval system, or translated into any human or computer

language, in any form or by any means, electronic, mechanical,

manual, or otherwise, without the written permission of Ultralight News.

By copying or paraphrasing the intellectual

property on this site, you're automatically signing a binding contract

and agreeing to be billed $10,000 payable immediately. Copyright Ultralight News - Ultralight Flyer. . |

|||||||||||||||||||||||||||||||||||||||||||||||