|

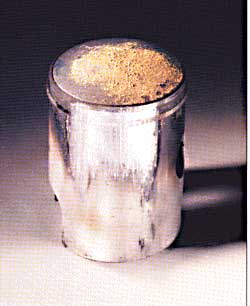

These pistons are normal in

appearance

The deposits on the piston

dome are from the oil and ash, fuel contaminants and unburned

carbon. As the thickness increases with operating time, the colour

gets brighter because of higher surface temperatures.

Depending on fuel and oil used, normal deposits may

also be brown, from light tan colour to almost black dark

brown.

Heavy black deposits on the piston dome are unburned

carbon accumulated because of too low temperatures resulting from

light load operation or too rich a mixture.

Brown or black varnish on piston side  below rings is

baked oil caused by combustion gases blow-by. Improper oil or poor

ring sealing is the cause. below rings is

baked oil caused by combustion gases blow-by. Improper oil or poor

ring sealing is the cause.

Very light scoring of the piston skirt is likely

from foreign material passing through the engine. It does not

suggest a problem in the engine and piston replacement is not

required.

Always check piston to cylinder wall clearance to

make certain the wear limit has not been exceeded.

Deposits should be removed from the piston dome and

cylinder head using a wood or plastic scraper. Excessive deposits

collection will increase the compression ration and reduce heat

transfer. |

|

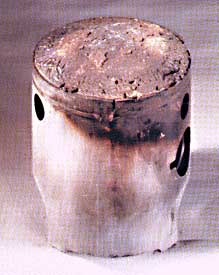

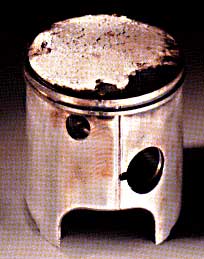

Seized Pistons

The piston shows yellow spots on the dome and

seizure marks on the skirt but there is no sign of metal aluminium. metal aluminium.

If you inspect an engine and find yellow or

yellow-orange deposits on the piston dome, that engine has

experienced an abnormal combustion condition known as detonation. In

this situation, combustion begins normally with ignition from the

spark plug but as the flame front moves across the combustion

chamber, rather than burning smoothly, the unburned portion of the

charge spontaneously ignites. This results in extremely high

temperatures and a shock wave heard as "pinging." What has happened

is combustion has been completed in about 29 degrees or crankshaft

rotation instead of the normal 50.

The oxide of calcium, an element found in 2 - stroke

oil additives, is normally near white in colour. At temperature very

near that of the melting point of the piston, the oxide will change

colour from white to yellow-orange and is an indicator that the

engine was overheated. The excessive heat results in rapid piston

expansion and possible failure of the lubrication film.

Possible causes:

too low an octane fuel used or fuel with too

much alcohol used

jetting too lean or failure of the fuel system,

i.e., clogged fuel line or filter, fuel tank not venting,

problem with fuel pump, carburettor air leak into

crankcase

spark plug heat range too hot

ignition timing too far advanced, possible

failure of the c.d.i. amplifier box

restricted exhaust system: back pressure too

high

overheated, loosely-installed spark

plug |

|

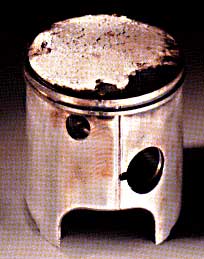

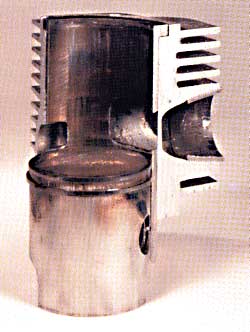

Piston dome

damage

The piston shows melted areas on the dome and seizure

marks on the skirt.

Detonation results in extremely high

combustion chamber temperatures. That rapid heat rise, if allowed to

continue, will heat combustion chamber deposits and spark plug

electrodes to the point that they will ignite the charge before the

spark at the plug does.

This condition is called runaway surface ignition or

pre-ignition. Once pre-ignition occurs, the temperature rise is so

rapid that melting point of the piston is reached while the engine

is still running. Metal will melt away beneath the spark plug or in

areas of high heat retention such as at the ring positioning

pin.

A complete breakdown of the lubrication film also occurs

resulting in severe seizure. Detonation always precedes pre-ignition

and the causes for this abnormal combustion are the same as those

for detonation.

|

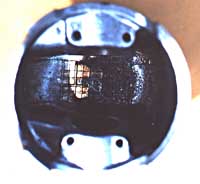

Piston damage by foreign

material

Piston shows imprints of small cylindrical parts on the

dome

Possible Cause

needles of broken wrist pin bearing trapped in

the squish area between the piston and head, destroy the dome,

ring land and rings.

make certain to check the condition of the big

end rod bearing and cage

|

Piston damage by foreign

material

Small ball shaped imprints on piston

dome

Possible Cause

foreign material, e.g. a pop rivet head, has

entered the engine and was trapped in the squish area, before

leaving through the exhaust port. In some cases the engine

continues to run normally until the ring

fails

|

Piston damage by foreign

material

Piston shows a vertical groove on the skirt

connected to the wrist pin hole.

Possible cause:

A wrist pin circlip has come loose and was

trapped in the transfer port window.

Note always use NEW circlips when

rebuilding an ultralight aircraft

engine.

|

Piston with lubrication

failure

(no signs of

detonation on dome)

Piston shows scoring marks below the rings on the

intake side.

Possible Cause

Snow or water has entered the engine and

destroyed the oil film

if the piston has scoring on the intake and

exhaust sides but the dome shows no signs of abnormal

combustion, the engine has been run with too little or no oil.

Check the operation of the oil injection system or the amount of

oil in the premixed fuel. Also, insure proper piston

clearance.

if the piston has scoring on the intake and

exhaust sides, no signs of abnormal combustion on the dome and

is very dark in colour, there has been a failure of the cooling

system. Check the fan belt, or coolant level

etc.

|

Piston with lubrication

failure

Piston shows dark brown deposits all over the

skirt.

Possible Cause

wrong oil quality, e.g. gear oil, automotive

oil

unnecessary additives have been used in the

fuel, i.e. octane boosters, high performance additives, upper

cylinder lubricants, etc.

|

Piston with lubrication

failure

Piston shows scuffing marks on the exhaust side of

the skirt without corresponding marks on the intake side. The

lubrication film failed under thermal load on the exhaust side of

the piston

Possible cause:

Poor quality of

oil.

|

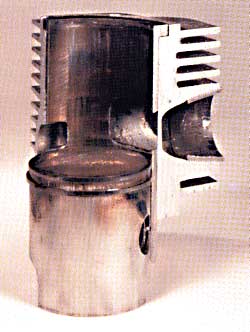

Piston ring

scuffing

Cylinder liner shows

scoring areas, which are exactly limited to the ring travel zone.

Beside the blue coloured vertical stripes, the surface is in good

condition. The rings show corresponding dark coloured marks. The

reason is a breakdown of the lubrication.

Possible Cause

improper break in period

poor oil quality

not enough oil in premixed fuel

low delivery rate from oil injection

system

|

Piston

fracture

Material fatigue fracture can sometimes be observed

on pistons of high speed engines, however, skirt fracture is usually

the result of excessive piston to cylinder wall clearance.

Other possible causes:

connecting rod breakage

damage due to bad handling,

crankshaft locking via piston

blocking

engine has ingested foreign

material

|

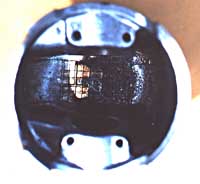

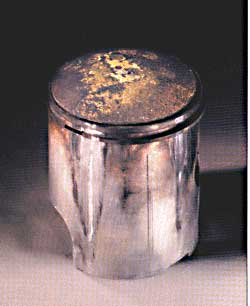

Underside Black Spot

The underside of

this piston has a black spot. The black spot is a carbon deposit

that resulted from pre-mix oil burning on to the piston because the

piston's crown was too hot. The main reasons for this problem are

overheating due to too lean carburettor jetting or coolant system

failure.

|

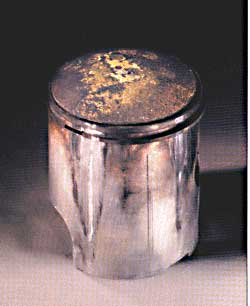

Chipped Crown

Drowned

This piston crown chipped at the top ring groove

because of a head gasket leak. The coolant is drawn into the

combustion chamber on the down-stroke of the piston. When the

coolant hits the piston crown it makes the aluminium brittle and it

eventually cracks. In extreme cases the head gasket leak can cause

erosion at the top edge of the cylinder and the corresponding area

of the head. Minor leaks of the gasket or o-ring appear as black

spots across the gasket surface. An engine that suffers from coolant

being pressurized and forced out of the radiator cap's vent tube, is

a strong indication of a head gasket leak. In most cases the top of

the cylinder and the face of the cylinder head must be resurfaced

when a leak occurs. It's important to check for warpage of the head

every time you rebuild the top end.

|

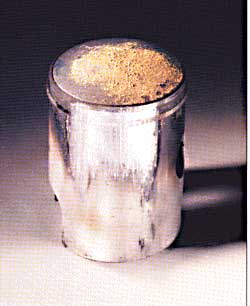

Shattered

Skirt

The skirts of this piston shattered because the

piston to cylinder clearance was too great. When the piston is

allowed to rattle in the cylinder bore, it develops stress cracks

and eventually shatters.

|

Snapped Connecting

Rod

The connecting rod of this engine snapped in half

because the clearance between the rod and the thrust washers of the

big end was too great. When the big end bearing wears out, the

radial deflection of the rod becomes excessive and the rod suffers

from torsion vibration. This leads to connecting rod breakage and

catastrophic engine damage. The big end clearance should be checked

every time you rebuild the top end. To check the side clearance of

the connecting rod, insert a feeler gauge between the rod and a

thrust washer. Check the maximum wear limits in your engine's

factory service manual

|

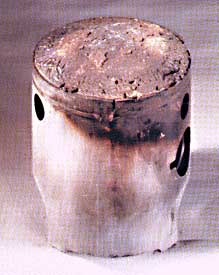

Four-Corner

Seizure

This piston has vertical seizure marks at four

equally spaced points around the circumference. A four-corner

seizure is caused when the piston expands faster than the cylinder

and the clearance between the piston and cylinder is reduced.

Another common problem of this type is a single point seizure on the

centre of the exhaust side of the piston. However this occurs only

on cylinders with bridged exhaust ports. The main causes for this

problem are too quick warm-up, too lean carburettor jetting (main

jet), or too hot of a spark plug range.

|

Multi-point Seizure

This

piston has many vertical seizure marks around the circumference.

This cylinder was bored to a diameter that was too small for the

piston. As soon as the engine started and the piston started its

thermal expansion, the piston pressed up against the cylinder walls

and seized. The optimum piston to cylinder wall clearances for

different types of cylinders vary greatly. For example a 50cc

composite plated cylinder can use a piston to cylinder wall

clearance of .0015 inches, whereas a 1200cc steel-sleeved cylinder

snowmobile set-up for grass drags will need between .0055 to .0075

inches. For the best recommendation on the optimum piston to

cylinder clearance for your engine, look to the specs that come

packaged with the piston or consult your Hirth distributor. |

Intake Side

Seizure

This piston was seized on the intake side. This is

very uncommon and is caused by only one thing, loss of lubrication.

There are three possible causes for loss of lubrication, no pre-mix

oil, separation of the fuel and pre-mix oil in the fuel tank, water

passed through the air-filter and washed the oil film off the piston

skirt.

|

Blow-by

This

piston didn't fail in operation but it does show the most common

problem, blow-by. The rings were worn past the maximum ring end gap

spec, allowing combustion pressure to seep past the rings and down

the piston skirt causing a distinct carbon pattern. Its possible

that the cylinder walls cross-hatched honing pattern is partly to

blame. If the cylinder walls are glazed or worn too far, even new

rings won't seal properly to prevent a blow-by problem.

|

below rings is

baked oil caused by combustion gases blow-by. Improper oil or poor

ring sealing is the cause.

below rings is

baked oil caused by combustion gases blow-by. Improper oil or poor

ring sealing is the cause. metal aluminium.

metal aluminium.