|

In ultralight aviation

there are three things that I have learned you can't be without.

Velcro, duct tape, and SAFETY WIRE. This article is about the

latter, Safety Wire.

I have had a couple of

rolls of the stuff around here for years. It comes in several

different thickness, for different applications. It is cheap, very

light, corrosion resistant, strong, and easy to install.

I first ran into "aircraft safety wire" at Sun N Fun in

1980, I bought 3 different spools - .020/.032/.041 and I still

have all of them sitting in the top of the tool box next to the

installation pliers. Back then they cost me about $5 bucks a roll

- last year I was pricing them and they now cost about $9. each.

But 1 roll will do the average guy a lifetime!

.020

is very thin, not very strong, but you can bend it around just

about anything. You use it to safety wire light bolts or fittings

where you need to bend the wire around a lot of

corners, and where the wire does not have a lot of pull on it.

.041

is extremely strong, because it is twice as thick and is

very stiff, and difficult to work with. It doesn't bend

easily and won't tighten around tight radius, you use it on wide radius turns where high strength

requires the extra effort to use it.

.032

is what I use the most - and ran out of first! If I was

shopping for a spool of safety wire this would be what I would

recommend. It is easier to work with, and reasonably strong

and should work on anything you might need to use safety wire on an

ultralight.

While

there are different materials used to make safety wire, brass an

aluminum, I don't recommend them. The type I recommend is 302/304

soft temper stainless s teel. teel.

One

of the things I quickly learned especially with the thicker wires

is that a safety wire tool makes the job a lot faster and easier.

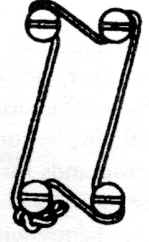

T here

are several different tools ranging from a unit that looks like a

screw driver, to a wire winder

tool, to a safety pliers. For a

klutz like me these make a beautiful finished job, with the right

tightness and strength. here

are several different tools ranging from a unit that looks like a

screw driver, to a wire winder

tool, to a safety pliers. For a

klutz like me these make a beautiful finished job, with the right

tightness and strength.

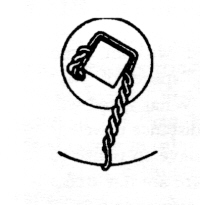

They are easy to use. I have the pliers type shown at right. You

wrap the safety wire around whatever it is you are securing, bring

both ends back into the pliers mouth, close the mouth down on the

wires, lock it (it has a little spring loaded locking mechanism)

then pull a round knob in the middle of the handle back - a lot

like those spinning tops we use to get as a kid. You know the ones

that you pumped up and down and the top would spin for what seemed

like hours! Am I dating myself here? Anyways when you pull on the

knob the plier handles turn and the wire wraps around itself.

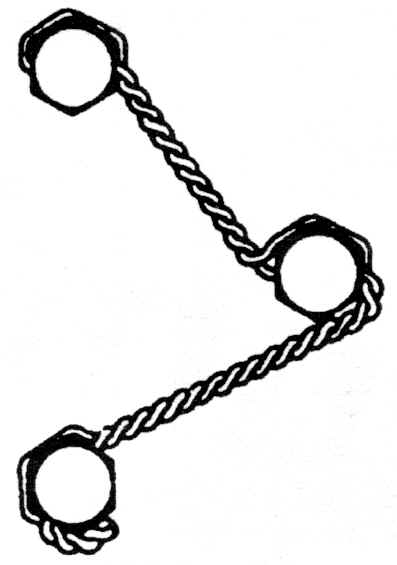

Areas

where you might use safety wire include around bolt heads, or nuts

where there is not means of locking them. Areas of special concern

are prop bolts, control system linkages, areas of movement, or

vibration. Another area of use is on turnbuckles to prevent them

from backing off in flight.

Several years ago I forgot to safety

wire the turn buckle on the cable operating the elevator on my

L'il Buzzard. About three hours into a cross country flight I

noticed that the stick movement was very sloppy and loose. A check

of the cable revealed the turn buckle had backed off 3/4's of the

threads in just 3 hours.

Other

areas that I use safety wire are:

-As hose clamps around the fuel lines, fuel pump, carb, primer

bulb. Using the pliers it is easy to use the .032 wire. I wrap it

around the hose two or three times then bring it back to the

pliers. Presto you have a clamp that is cheap, effective, and easy

to remove.

-As

replacements for the older style EGT probe clamps. I have been

doing this for years, after the one of the clamps broke off and

went through my prop. You wrap two or three wraps around the

probe, place the probe into the hole in the manifold, (you may

have to use a couple of washers to space the probe out so it does

not touch the other side of the manifold) then wrap each end of

the safety wire around the exhaust manifold a couple of times - then bring

the two wires together and hook them into your pliers, and pull. (.040)

-On

the 53/582 you won't find a clamp small enough to go around the

vent on the top of the cylinder head (water pump outlet on

inverted engines) two or three wraps of safety wire does the

trick. (.032)

-On

the exhaust springs. Run a piece of safety wire through the center

of the spring, onto the spring hook then back through the center

to the other spring hook, use your pliers to tighten. THEN fill

the spring FULL of silicone.

-On

the rotary valve tank cap. If you look you will see that the cap

has a little hole in it at the bottom of the threads. Hook a piece

of safety wire though it and then secure it to the little tab on

the rotary valve tank. That's what it's there for

-To

secure your airfilters to your carbs. If you check out the alert

bulletins on site, and the accident statistics you will find a

number of instances where the airfilters have come off and gone

through the prop.

-Secure

spark plug caps to spark plugs, especially in inverted engine

installations like the Challenger.

-Secure

the carb nuts and studs on the 185 Rotax engine used on the Lazair

ultralight. They had a tendency to vibrate out, so we would drill

a hole in the stud and nut then safety wire it back onto the carb

to stop them from turning.

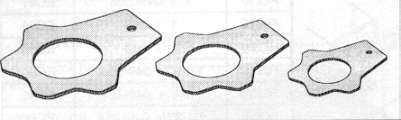

Of

course the main area that you will find safety wire used in on

prop bolts. In fact it was the first thing that a conventional

pilot pointed out to me on my Challenger, the bolts in the prop

hub weren't secured and could vibrate and back out. This

results in a loose fitting prop which shears the prop bolts!

On

my old Buccaneer I replaced the little rings on the rudder control

pins with safety wire when one of them came off in flight after I

taxied through some mud and weeds.

A

bolt that is properly safety wired like that on the right just doesn't just hold the fastener in place, it serves to

pull it tighter. Each bolt holds the other and actually tightens the

other if it starts to come loose.

How

to Properly Install Safety Wire

There

are a couple of basic rules to follow when safety wiring

something.

They are:

-If

you are safety wiring a nut or bolt FIRST torque the nut or bolt

to its proper torque. Where possible align the holes that are

going to be used to safety wire the units in place. BUT DON'T OVER

TORQUE or UNDER TORQUE them to achieve this!

-After

installation the safety wire should be tight! So as not to allow

the unit(s) to move.

-Safety

wire should always be installed so as to make the nut or bolt

"TIGHTEN" itself when the safety wire has been

installed. That is the safety wire should come around the top of

head of the bolt/nut and back onto the securing unit so that the

safety wire PULL is in a tightening direction!

-NEVER

over stress the safety wire. This weakens it, which could cause it

to break under vibration or load. This is generally caused when

you "over wind" the safety wire. Safety wire should

never be nicked, or kinked.

When cutting the safety wire always

leave 4 to 6 turns after the loop. REMEMBER always bring the

safety wire AROUND the head of the bolt/nut in a tightening direction, in as small a contour to the bolt/nut as you can get.

A

Klutz's guide to using a set of safety wire pliers!

After

you have wrapped the safety wire around the object, grip both ends

of the wire in the jaws of the safety wire pliers and slide the outer sleeve down with your thumb to lock

the handles.

Now

grasp the knob located in the middle of the pliers and gently pull

out. This will cause the plier handles to turn, twisting the

safety wire!

When

you have the amount of twists required, grasp the handles and

squeeze. This will release the safety wire from the jaws of the

pliers.

Use

the cutters in the jaws to cut the safety wire to the proper

length, then bend the end of the wires over so that you don't poke

yourself on them the next time you reach into work on

something.

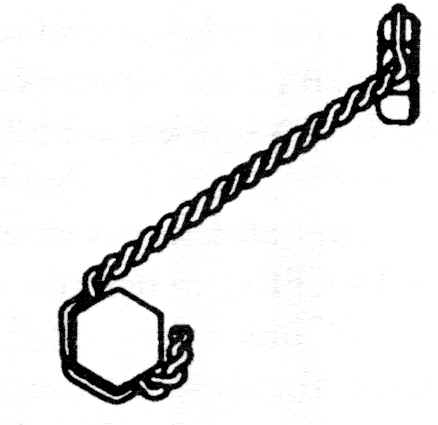

Securing

the rotary valve tank cap on a 532/582 Rotax engine.

Find the hole in the cap, it is at the bottom of the threads in

the cap. Run a piece of safety wire through it, and pull it back

out so you have about 6 inches of safety wire.

Move down to about

an inch from the pliers end of the safety wire. Hook the pliers up

to the safety wire and twist until you have a nice spiral coming

up to the pliers. Install you cap onto the rotary valve tank.

Now

wrap the safety wire around the tank - in a tightening direction

and connect it to the little standoff on the rotary valve tank.

Hook one end of the wire through the standoff, grab both wires

with the safety wire pliers and twist gently. You don't want to

have too many loops incase you have to take the cap off.

|

teel.

teel. here

are several different tools ranging from a unit that looks like a

screw driver, to a wire winder

tool, to a safety pliers. For a

klutz like me these make a beautiful finished job, with the right

tightness and strength.

here

are several different tools ranging from a unit that looks like a

screw driver, to a wire winder

tool, to a safety pliers. For a

klutz like me these make a beautiful finished job, with the right

tightness and strength.