Rotax 532, 582 cold seizure

Rotax Aircraft Engine Cold Seizure

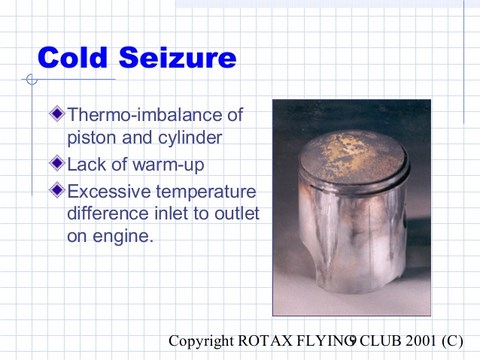

This is probably the most reported problem that occurs on a 532/582 Rotax liquid cooled engine. In many cases the pilot doesn't even know that he has had a cold seizure! So what is it and how does it happen? Remember this is a liquid cooled engine (cold seizures also occur on air cooled engines and for the same reason).

Here is an example of a situation in which a cold seizure could occur.

A pilot flying on skis is sitting at the end of a runway, impatiently waiting for traffic to land and clear off the runway. During this time his engines has been idling. The runway is finally clear and he applies full power and takes off , about two thirds of the way down the runway and about 500 feet in the air the engine suddenly quits. The pilot is forced to make an emergency landing. Once down on the ground the engine starts and runs again.

At this point the pilot will usually do one of two things, try to find out why the engine quite - or start the engine and try another take off.

What has happened is that the engine coolant has been cooling in the rad, in winter in cold temperatures, this can mean that the temperature is down below 100 degrees F. The engine on the other hand is under load and is creating heat, the pistons are expanding. As the cold liquid enters the area around the cylinders, the cylinder shrink and this causes a cold seizure.

The problem is that cold seizures in most cases seizure only a part of the ring. This allows enough compression for the engine to continue to run. One of the first things pilots will notice after a cold seizure is that they generally cannot achieve full rpm on run up and climb out.

In one case over a 50 hour period a pilot repitched his prop 4 times to a finer pitch, and dejetted his carbs down to 148 main jets from 165's before calling for help.

The use of adjustable radiators, thermostats, proper flow rates , the use of EGT gauges, and water temperature gauges, and proper pilot take off and landing procedures all help in eliminating Cold Seizures.

Rotax 532, Rotax 582 fuel System

The fuel system supplied by Rotax is one of the most trouble free in the industry, when installed correctly! The majority of the problems reported are related to either improper installation or modification. There are several components in the fuel system. Lets' quickly go through some problem areas.

The Rotax fuel pump should be mounted ABOVE the vacuum hole. The pump should be no more than 12 to 18 inches away from the vacuum source The pump should be mounted flat, that is with the vacuuming inlet facing down and the top side of the pump facing the sky. The pump should be rubber mounted, in some kind of an airflow, and away from heat.

All lines should be securely clamped, and the line operating the pump should be of a thicker wall thickness so that the sides do not collapse . All lines should be inspected regularly and replaced yearly! Especially if the engine is left stores outdoors.

If an electric pump is to be installed run the pump in a parallel configuration with the fuel pickup prior to the vacuum pump and inserted back into the system, after the pump. Make sure that the electric pump you select does not put out more pressure than is recommended or you could cause your carbs to fail.

Rotax fuel system inspection

Always use a fuel filter or gascolator and mount it to the lowest point in the system. Most of the fuel filters supplied in the industry for our use should be replaced every 75 hours of operation .

Other items that should be inspected and replaced at the first sign of wear, or deterioration are the oil filter, carb intake rubbers, and the carb needles and clip holders. Wear of failure of the carb intake rubbers, and needles and or clip holders is an area of repeated failures.

Another reported problem is the failure of the primer valve used to start the engine with. When it fails it creates a problem especially for aircraft with wing tanks, by allowing fuel to flow through the primer into the carb. This will flood the engine with fuel and eventually cause engine failure.