Rotax 532, Rotax 582 ignition system troubleshooting

Rotax 532 / 582 Ignition system

The only reported problems to date with the ignition system on the 582 Rotax have been with ignition coil failure. This is the external coil mounted on the carb side of the engine by the water pump outlet. Failure is detected when a loss of rpm is noticed and or an ignition check is done on the system during preflight. The only solution is to replace the coil with a new one.

The 532 Rotax has a history of ignition problems. The ignition coils have been reported to fail, and my recommendation is replacement at 150 hours, or at the first sign of problems. Another thing that plays havoc with the 532 ignition is when the magneto crankshaft seal fails.

Failure of this seal allows oil to come in contact with the points and condensers. This in turn can cause a poor condenser ground which will cause erratic engine performance. Oil on the points will usually result in hard starting and loss of rpm. Another problem with the points ignition system is that the point arms WEAR DOWN and this will CHANGE the ignition timing. This can result in an engine failure due to a hole in the top of the piston. The 532 engine should have its ignition timing checked every 50 hours or twice a year.

Some pilots are using resistor plugs to suppress engine noise when then are using radios. On the 532 you can use EITHER a resistor plug OR a resistor cap but you CANNOT USE BOTH. The 532 ignition is not strong enough to run both a resistor cap and a resistor plug.

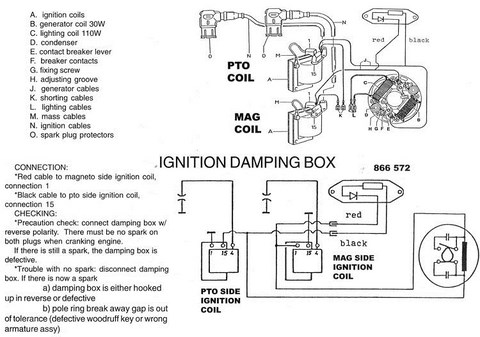

Some Rotax 532 owners have reported the ignition missing in mid range when they have recently installed new coils or reconnected the ignition suppressor box.. When connecting the coil leads on one coil the ground wire will go to the #1 side of the coil, with the points wire going to the 15 side. ON THE OTHER COIL the 15 is the ground and the #1 wire goes to the points.

On 532, when connecting the ignition suppressor box the blue/red goes to the black wire and the red goes to the blue/black.

When hooking a tachometer up to a 532 hook the tack to the generating coil wires. DO NOT connect them to the ignition wires.

While not part of the ignition system problems have been reported with the tachometer circuit on the 582. For some reason the circuit seems to destroy tachometers, some in as little as a few minutes while others may last a year or so. My only suggestion is to buy a tachometer from a company that has more than a years warranty or that will stand behind their products. Aircraft Spruce and Skysports are two companies that I recommend for this reason..

Rotax 532, 582 liquid cooled aircraft engine troubleshooting

Engine Top End

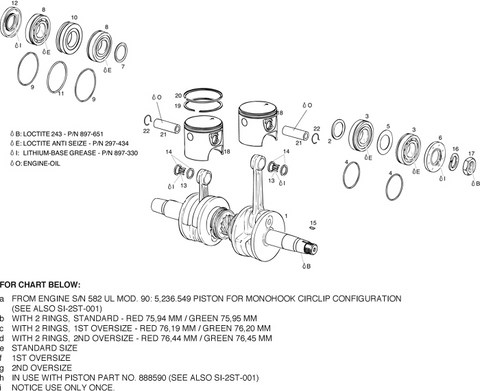

Several problems have been reported by pilots with the top end of the 532/582 Rotax engine. The top end consists of engine parts above the crankcase. On the 532 failure of the wrist pin bearing is one of the most reported. Rotax updated the 582 with a new style of piston and bearing. The new piston has a hole on the intake side of the piston which allows more lubrication into the wrist pin bearing.

The new wrist pin bearing also has 31 bearings and no cage, this doubles the bearing area. This update can be done to a 532 . To do it you will require an old 582 piston, use it as a template for drilling the hole in the side of the piston and then update to the new wrist pin bearing.

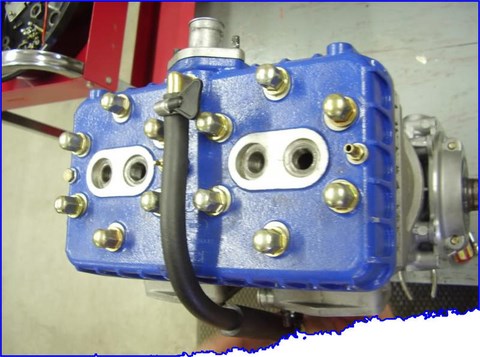

The next most frequent problem is cold seizure which we have already dealt with. Rotax has also update the water pump impeller on both the 532 and 582. The new impellers now have a 6 mm hole in them, and are made of a more durable heat resistant material. Another update has been to the 582 cylinder head.

There are now two vents one on either end of the cylinder head. When connected back into the rad system these vents prevent air from being trapped in the front cylinder during climb out, which prevents engine seizure.

The 532 can be update to this system easily - but it does require the removal of the cylinder head and the drilling and tapping of the head to allow for placement of the vent.

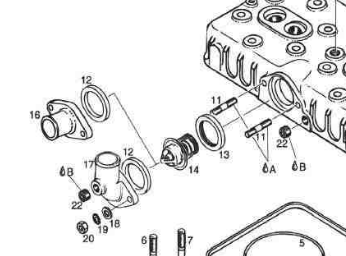

Thermostats present another problem-while it is recommended that the 532 and 582 be run using thermostats they have been reported to fail, generally a the solder joints. It is recommended that the thermostat be inspected every 6 months or 50 hours.

Once again I cannot over emphasize when filling the rad system use only DISTILLED WATER, any other water will lead to corrosion starting in your engine especially in the cylinder head.