Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's

standard

dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a

type

specimen book. It has survived nt only five centuries, but also the leap into electronic typesetting, remaining

essentially unchanged.

Troubleshooting the Rotax line of two stroke ultralight aircraft engines.

Troubleshooting the Rotax line of two stroke ultralight aircraft engines.

UltralightNews.com

Troubleshooting the Rotax line of two stroke ultralight

aircraft engines.

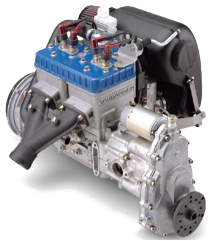

Exhaust, carburetor, fuel pump, and reduction drive are all obtainable, in various exhaust configurations

and gear drive combinations. These factors have all contributed to its acceptance by manufactures and

pilots.

But like any other product used in today's market, especially one where the use is so varied,

problems have occurred.

Some of these problems can be traced directly to the manufacturer of the ultralight aircraft, others to

the owner, and others to the engine.

In an effort to make more pilots aware of some of the associated problems, and their possible solutions, the following is a

synopsis of reported problems encountered by Rotax engine users, and some possible solutions.

These are general problems found in most cases with all the Rotax engines, in further reports we will deal with each

engine

separately.

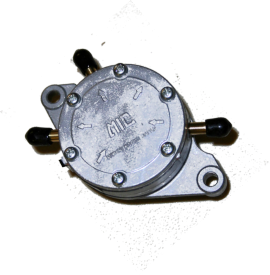

Fuel Supply: The Mikuni fuel pump is the primary pump used in the ultralight industry, and with the

Rotax engine.

The following is a list of items to be considered and adhered to:

When mounting the Mikuni fuel pump make sure that it is no more than 11 inches away from the impulse

outlet on

the engine.

Make sure that dual Mikuni fuel pump is mounted away from any heat source, and that it is

positioned so that the vent on the Mikuni pump vacummn inlet is facing down.

The vacuum line used to connect the Mikuni pump to the engine impulse outlet is of a much

thicker wall thickness than regular gas line, and is not effected by heat.

The fuel line and vacuum lines are generally exposed to sunlight in most older configuration of

ultralights and it is suggested that they be checked on a regular basis for cracks, discoloring, or UV deterioration

Yearly replacement is a good preventative maintenance approach.

VENT