Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has

been the industry's standard dummy text ever since the 1500s, when an unknown printer

took a galley of type and scrambled it to make a type specimen book. It has survived not

only five centuries, but also the leap into electronic typesetting, remaining essentially

unchanged.

Troubleshooting the Beaver family of ultralight aircraft - Wing Failures!

UltralightNews.com

Lorem Ipsum is simply dummy text of the printing and

typesetting industry. Lorem Ipsum has been the industry's

st

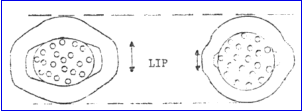

The most common method of anchoring the

drag truss in an aircraft wing has two

lengths of cable, per wing bay, with each

end firmly anchored to a corner.

ummy text ever since the 1500s, when an unknown printer

took a galley of type and scrambled it to make a type

specimen book. It has survived not only five centuries, but

also the leap into electronic typesetting, remaining

essentially unchanged.

Beaver, Beaver ultralight aircraft, Beaver RX 35 ultralight

aircraft, Beaver RX 550 ultralight trainer troubleshooting report.

slipped along the cable leaving a trail of copper coloured residue.

Two of the specimens installed by the Nicopress manufacturer were tested. Both failed at 800 lbs tension, exceeding the rated

strength of 600 lbs. The mode of failure was such that the sleeve did not slip, but

rather strands of cable started to break in the vicinity of the sleeve.

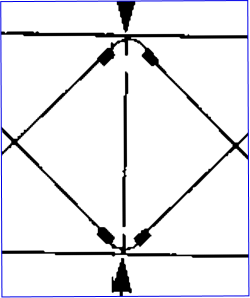

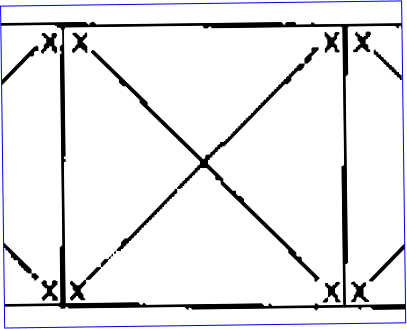

Beaver RX 550 Wing Failure Report Conclusions:

The structural integrity of the wing in the drag plane depends on the gripping strength of the stop sleeves in the corner of each bay. Although the correct stop sleeves had been used, it was considered that they were installed using the incorrect tool, which resulted in a lower gripping strength. The most heavily loaded stop sleeve in the structure had a gripping strength of 60% of its rated value. The most common method of anchoring the drag truss in an aircraft wing has two lengths of cable, with each end firmly anchored to a corner. The RX 550 is made up of only two cables, which zig-zag through the wing, and are anchored in the corner of each bay by a Nicopress stop sleeve. In order for this method to work, the stop sleeves must be able to react sufficient force that they do not slip. If they do slip, the Beaver RX 550 wing will collapse in the drag plane!