Ultralight reduction drive problems

Ultalight Aircraft Belt drive systems:.

This was the second type of system used in ultralights. These drives used an upper and lower pulley, of different diameters, and a single or series of belts, to reduce the prop RPM. This allows the use larger propellers for better performance and reduced noise.

When buying a craft equipped with a belt drive system check out the two pulleys for wear or damage, the condition of the belts, shaft bearings wear . Also check the reduction drive casings for signs of cracks or damage .

Early model Quicksilver MX aircraft used a coupler to connect the driveshaft to the engine. This coupler failed and was updated to a large diameter coupler ).

Check out: http://www.ultralightnews.com/quicksilver-mx-ultralight-aircraft-troubleshooting/

Many early designs used belt drive systems on the Rotax engines. On early model 277 engines over tightening the drive belt can result in failure of a plastic liner used to support the crankshaft PTO end bearing. Failure has also been reported on 377/447/503 crankshafts using belt drive systems.

If purchasing an aircraft with over 100 hours on it using a belt drive on a Rotax engine, a complete tear down and rebuild of the engine is recommended!

Ultralight Aircraft Planetary reduction drive systems:

Several planetary systems were used over the years on ultralight aircraft. Most are no longer available. One widely used system was the Winters reduction drive. Failure of this system forced the manufacturer to stop production.

Failure has occurred at the output shaft, resulting in the propeller exiting the aircraft. Failure also occurs in the aluminum ring supporting gears inside the casing, usually resulting in seizure of the drive system, resulting in a forced landing.

Recommendation: If the craft you are considering, has this re drive system; DO NOT FLY until you change the drive system. Consult aircraft manufacturer or someone knowledgeable in the industry for advice.

Rotax A & B Reduction drives used on ultralight aircraft

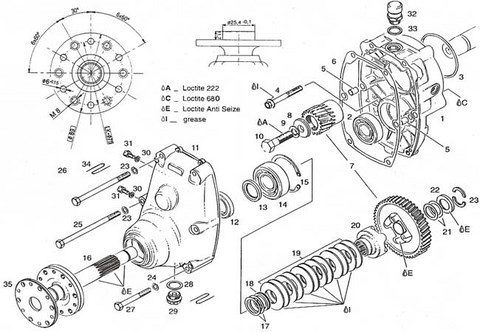

Rotax gear drive: Updates have occurred to the Rotax A/B reduction drives.

The first was an update from 2 groups of four spring washers on the output shaft to 3 groups of 4 washers . Reason -- failure of the spring washers resulting in hard starting.

The output prop hub was also update from a two piece steel shaft/aluminum hub arrangement to a one piece steel shaft and hub.

Reason - Failure of the aluminum hub, and stripping of the prop bolt retaining threads in the hub.

Another update was going from a 3 bolt gear box to engine adapter plate to a 4 bolt engine adapter plate.

Reason - failure of the bolts holding the adapter plate to the engine, causing loss of drive, or damage to engine case.

Rotax A & B Reduction drive Updates

Rotax gear drive: Updates have occurred to the Rotax A/B reduction drives.

Vent cap update-Rotax has updated the vent cap on the gear drive. This update helps prevent loss of gear drive oil due to siphoning action of the propeller, or gear drive internal pressure, which can result in gear drive failure due to lack of oil .

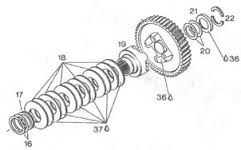

Another update changes the main gear in the drive from a gear with holes in the sides of it to a solid gear . Failure of this gear was evident by missing teeth or cracks running from the gear teeth to the holes.

The Dog hub has also been update from a two dog hub to a 4 dog hub. On the old system if the engine has a prop strike the gear drive would have to be taken apart to reposition the hub. With the new 4 hub system it simply jumps to another hub .

On C drive model gear drives the torque value has been updated on the gear retaining nut. Another common problem with the C drive is a leaking seal at the back of the drive. Signs of failure of this seal will be gear oil coming out of the two holes on the side of the drive, where the rubber coupler is visible.

Cost of Rotax reduction drive $ 800. (model A or B)

Cost of Rotax reduction drive $ 1100. (model C)

Cost of new Haegar Belt drive system $ 900.

Index

Approximate prices

Cost of replacement belts $ 8. (each-4 belts required)

Cost of replacement single belt system $ 35.00 - $ 50.

Cost of bottom pulley $ 60.

Cost of top pulley $ 160.

Cost of flex coupler per Ultralight systems $ 150.

Cost of standard coupler per Ultralight systems $ 49.95

Bearings $ 15. - $ 35. (each)

Rotax Gear box update kit $ 35.00

Gear hub update $ 42.50

Rotax drive gear $ 98.00