Rotax Bing 54 carburator updates

Rotax has introduced a modification to the vent tubes, they now use one vent line with holes at the bottom. This provides for even pressure distribution to both sides of the float chamber.

Make sure that the vent or balance tube is not pinched off in any way, as it will effect the carb mixture.

For a short period of time Rotax shipped out carburetors which had two pins in the slide throat area. It was found that these pins had a tendency to break off and enter the engine possibly causing piston damage.

These carburetors are on recall, and if your craft is equipped with one it is recommended that you contact your nearest authorized Rotax engine service center for a replacement carb body.

Identification of this problem carb can be done by simply looking at the side of the carb opposite the idle adjustment screw, if two pins can be visibly seen then your body needs updating, if a solid block is found you are okay.

Another problem encountered on early model carburetors equipped with a plunger on the side of the carb, was the bending of the float arms. Because the plunger, when used presses down on one side of the float assembly it was found that over a period of time bending of the float arm occurred resulting in improper fuel levels in the float bowl chamber.

If your craft is equipped with this plunger a simple cure is not to use it.

Another problem area is in the top cap on the Bing carb, the one that screws down onto the top of the carb body and retains the throttle cable. In what looks to be the center of the cap is located a screw in fitting, which can be used to adjust the length of throttle cable.

In fact the screw in fitting is not located in the center but is off to one side. If installed incorrectly this can result in wear on the throttle cable where it passes through the bottom of the fitting, as the cable now pulls at an angle and rubs against the outside of the fitting during throttle operation.

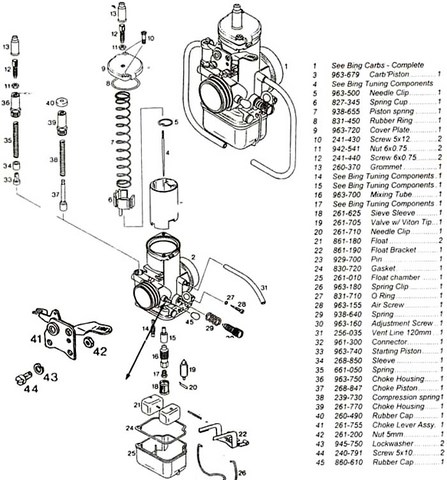

Bing 54 Carburator parts

One other problem on early model Bing carburetors and intake manifolds was that the two aluminium protrusions, which are coupled together with a rubber intake manifold flange, were smooth. This allowed the carb body to rotate in flight, in some cases causing engines to leak excessive amounts of fuel and or simply quit.

Later model engines were kernelled on both the intake and carb sides to prevent this from happening. Also make sure that the rubber intake manifold flange is installed with the arrow on its side pointing towards the engine, for proper fit.