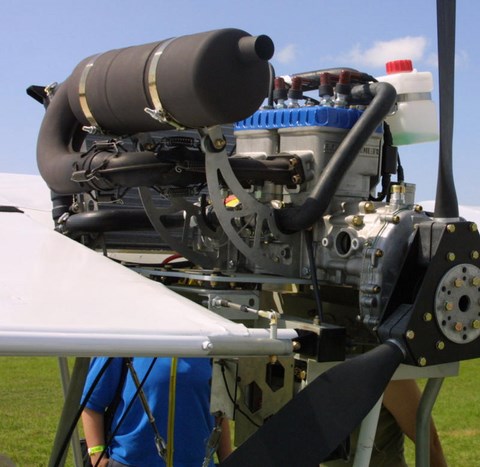

Rotax exhaust system problems

Exhaust Systems: Various ultralight pilots have complained about problems with the Rotax exhaust systems. Most have complained about the side mount exhaust splitting at the elbow, and directly along the welded seam.

Others have complained about the baffle inside the exhaust breaking away and clanging around inside the exhaust canister.

Others have complained about the spring retention brackets wearing through, or the springs breaking because of the angle that they have to be mounted to reach the brackets.

The solution to these problems are varied but in most cases are not the fault of the exhaust system.

The first problem can be solved by simply rewelding the exhaust, we have gas welded, arc, welded and tig welded exhaust systems. Most are still flying today with this repair.

The problem is generally caused by rust forming at the exhaust manifold and muffler joint, thereby making this a solid joint rather than a flex joint. The solution is to coat the ball socket with an asbestos silicone available through your nearest Rotax engine service centre.

Another cause is the way the exhaust is mounted, in many cases it is mounted solid, and this causes excessive vibrations and wear leading to breakage, change your mount so the system is rubber mounted and allowed some flexibility.

Rotax ultralight aircraft exhaust problems

The baffle problem has been eliminated, in most recent exhaust models, but was a problem in early models, the solution is to open up the canister and reweld the baffle back in, or buy a new exhaust.

The third problem with the exhaust spring mounting tabs is to reweld the tabs so that the springs pull straight not at an angle, and also so that the distance between the two tabs is just enough to tension the springs. It is also recommended that these springs be safety wired, and that a bead of high temp silicone be run along the spring coils, this prevents a harmonic vibration from setting up and also aids in preventing the spring from separating, if it breaks.