a) Compare old rings with a set of new rings with a slide gauge.

b) Insert the rings horizontally (separately) into the cylinder1 just above the ports. The gap between the ends of the ring should be within the tolerances of .012"

- .015". In order to make sure that the cylinder itself is not worn, insert new rings and compare the gap.

3.a)The piston and its bearing can be checked and replaced as follows:

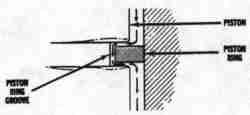

Measure the clearance in several places around the piston ring after having them fitted to the piston. The clearance between the piston rings and their grooves should be approx. 0.002" - 0.003".

NOTE: The grooves in the piston for the rings should be cleaned from carbon deposits by using an old ring or scraper.

b) Rock the piston up and down on the pin to check for excessive play, which indicates worn needle bearings.

c) Check piston for scoring or other damage:

Move the piston. close to the top dead center from side to side in the cylinder and check the

clearance, which should have a minimum of .006" (1nsert the feeler gauge all the way down along the piston).

d) If piston or piston pin bearings have replaced (any of the above checks are such steps) remove the retaining ring side of pin push the pin out.

to be requiring on each

e) Check the needle bearing and the bearing journal diameter for wear.

f) Reinstall piston as described above, in reverse order and make sure that spacers and retaining rings are in place.

4. Check the cylinder for scoring, cracks, damaged spark plug threads, and check. diameter of cylinder bore with a gauge, if available.

Make sure that all dirt is removed from the cooling fins and all carbon is removed from exhaust port.

Reinstall cylinder as follows:

a) Clean cylinder gasket surfaces and replace the old gasket with. a new one. Use a drop of

sealant underneath the cylinder gasket were the crankcase halves join.

b) Put some oil on the cylinder walls so that the cylinder slips easy onto the piston.

c) The engines have "pinned" piston rings. Care must be taken that the ring gaps fall on the retaining pins in the ring grooves as the piston is inserted into the cylinder.