Lazair Ultralight Aircraft Newsletter Number 5 June '82 |

|||||||||||

|

|||||||||||

|

The probability of survival is equal to the angle of arrival. |

|||||||||||

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

Lazair Ultralight Newsletter |

|||||||||||

|

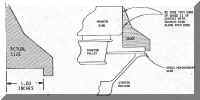

5.1 Lower strut plug installation Early Lazairs (the ones

with the spoked wheels) were designed so that the P16 strut plug

extended beyond the end or the

T27 strut tube. Later models (with

the "Tundra Tires") have a larger diameter axle (i~)ich

increases the spacing between the F6 gussets to 1 1/4 inches) and therefore

the P16 must be installed so that it is flush

with the

end or the T46 strut tube. If

you have one or the first few kits shipped after the changeover, your

assembly instructions regarding the position or the P16 may have been somewhat

ambiguous. Please check to make sure

that ~our P16's are installed as shown below, and there are two

315 bolts in each strut plug (P17's as well as P16's).

As a secondary check. you can measure If it is necessary to

reposition your P16 plugs, it should be possible to do so without having

to scrap either the

strut or the plug. ~whenever

possible. use existing holes in the strut.

Rotate the~Pl6 and drill new holes in it as necessary.

Make sure the center or the lower strut hole is at least 1/2

inch from the end or the strut. 5.2

TINY Bubbles IN THE LINE Now that we have

eliminated the primer bulb. the in-line filter, and the tee fitting. the

problem or bubbles in the

fuel line should be

gone forever - but now we have round a new source or bubbles - this one

even more intriguing than the others. After one or our factory demonstrators displayed some noticeable bubbles. we checked the fuel line for leaks and determined that there wass no place where air could get into the line - this is the main advantage or the submersible fuel filter. Since the bubbles appear to emanate from within the fuel itself, it has been determined that the bubbles are not air, but vaporized fuel. The exact cause or these bubbles is difficult to determine, but it is believed that water in the fuel effectively plugs the filter. Then each time the diaphragm in the fuel pump is pulsed there is a momentary reduction in pressure in the fuel line. This reduction in pressure lasts for only a fraction or a second, but it is sufficient to cause a small amount of fuel to vaporize and form a tiny (almost invisible) bubble. These gradually merge to form larger bubbles as they migrate toward the carburetor.

This

theory has not been proven, but it has gained credibility when the fact

that any time the problem

has occurred, it has been

eliminated (completely) by removing the felt from the fuel filter and

rolling and stretching it to get rid or the water. We

are now investigating the use or other materials (such as a brass

screen) to eliminate the

felt filter. In the meantime,

check your fuel lines for bubbles frequently while flying.

Check your filter periodically (especially if you suspect there

may be water in the fuel). Roll

the felt between your hands, stretch

it, compress it and then put it back on. 5.3

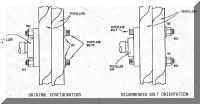

CENTERING THE STARTER ASSEMBLY To

prevent possible damage to the starter pulley on the rotax engine, it is

essential that the starter

pawl assembly be centered properly.

If you remove the

starter assembly from the engine or if the engine is removed from the

engine mounting assembly, the starter assembly position should be

checked after re-assembly as follows: First,

make a measuring gauge from thin sheet metal as shown.

Use this gauge to

check the radial spacing between the

starter housing and the magneto ring.

Check the spacing at four places (approximately equally spaced)

around the 5.4

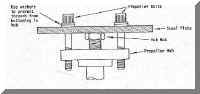

PROPELLER BOLTS Since the introduction or the rotax engine in November '81 we have had three reports or broken propeller bolts. After examination, it was determined that one or these failures was a result or the engine being run for a considerable length or time with the propeller bolts loose. The other two resulted Prom the propeller bottoming on the crankshaft nut rather than seating properly on the hub. A special notice regarding this potential problem and a suggested method or checking the depth or the counter bore in the propeller was mailed to all owners or kits shipped prior to January '82 (those who we thought could have experienced this problem) but it appears that some or the notices either did not reach their destination or were ignored by their recipients. Please check the installation or your

propellers and ensure that they are properly seated on the propeller

hub. The depth

or the counter bore may be

increased slightly if necessary to allow the propeller to fit properly

against the hub.

To

reduce the possibility or a bolt failure (even if a propeller is improperly

installed) all kits shipped after May 17, 1982 have the bolts inserted

through the hub in the opposite direction to that in This requires drilling

out bolt which goes

through configured, the bolts were the

holes in the propeller hub to 5/16 inches diameter, and allows the part

of the hub (where

the stress is highest) to be the full diameter.

As originally threaded into the propeller nub. The threads on the bolt

not only reduce the cross sectional area of the bolt by approximately

forty percent, but they also introduce a stress concentration, which, under

fatigue loads, can be as high as 2.7 to I.

By reversing the bolts, the threaded part of the bolt is moved

from the area of maximum stress to

the area of minimum stress.

To

insert the bolts as recommended, it will be necessary to remove the

propeller hub from the crankshaft.

If you don1t have a gear puller, the following method

may be used: First, loosen the crankshaft nut and screw it off until it

protrudes about 1/16 of an inch past the end of the crankshaft, then

remove the propeller hub using a puller made from 1/4 inch steel and the

two propeller bolts as shown. If

you don't have a piece of steel handy, you can use one of your nacelle

weights and drill a couple of 3/8 inch holes in it.

Tighten the two

bolts alternately, slowly

To reinstall the

propeller hub, make sure the taper on the crankshaft and the hole in the

hub are absolutely clean and free

of grease. Apply a small amount of Loctite 242 or similar locking compound,

fit the hub onto the shaft and tighten the nut to a torque of 35 root

pounds. After the propellers are installed, the NSC propeller nuts should be tightened to a torque of 15

foot pounds. 5.5

UP YOUR CABLES In update number 2 we

discussed the problems of catching long grass in the cables.

To alleviate this problem, all

new Lazairs have the cables attached to the stabilizer at the end of the

spreader (TlI or TilS) rather than at the lower (outboard) corner as was

done originally. If you wish to modify your Lazair to move the cables uo~ it

is a relatively easy change provided that you have access to a Nicopress

tool and sleeves, since the cables must be shortened.

If you can't locate a tool readily, check with your local EM

chapter. 5.6

RUDDERVATOR PUSHRODS In a previous update

(item 4.4, December '81) we reported on a potential wearing of the T26

pushrods where they pass through the F32 pushrod guides. To alleviate this situation, kits shipped in May and 3une of

1982 included a roll of 5421 or 5423 abrasion resistant tape.

We have been flying factory demonstrators

with this tape installed for over four months and have not

encountered any difficulties. However,

if the tape is not properly installed, or if it becomes damaged (by

mishandling while assembling or trailering the aircraft) there is a

possibility that it could come loose and get wedged in the F32 making it

difficult to move the ruddervator pushrods. Although this has not

happened, the possibility does exist.

Therefore, if you

have the tape on your

aircraft, it is recoemended that the tape be recoved from the pushrods

and discarded. If you

received the tape with your kit, but nave not installed it yet, don't.

5.7

D-CELL NOSEERIBS The owner of a

highly modified Lazair reported recently that several of the foam

noseribs inside his D~el1 had moved out of position.

This was one of the earlier kits with the .016 inch D~ell skin,

(kits A192 and subsequent have a .020

inch D-cell skin) and was fitted with relatively heavy reduction units

and very large propellers. Although this is believed

to be an isolated case, it is recommended that all

owners check the position or their nose ribs occasionally

(especially in the area or the engine nacelles).

This can be done easily by tapping along the top or the D-cell

(about 4 inches ahead or the main soar) and listening for the ribs. There

should be a rib every 4 inches. if

you should ever get an indication that two or more adjacent ribs are out

or position, drill out a few rivets so that the D-cell skin may be

lifted sufficiently to look inside (with

the aid or a flashlight). Any displaced ribs should be

repositioned and bonded in place with panel adhesive.

To avoid loosening the D-cell skin, remove only as 'many rivets

as necessary and use tools made

from coat hangers to fish the ribs into position. It should be noted that

because of this possible problem, the use of Rotax engines on a Lazair

with .016 inch leading edge skin is not recommended. 5.8

CARBURETOR STUDS In spite of the fact that

carburetor studs are installed with Loctite and the carburetors are

attached with metal to metal shake proof nuts,

we have had three reports of carburetor studs or nuts working

loose on the Rotax engines. while

it is unlikely that this would ever cause a carburetor to

fall off , it could

become loose enough to

cause an engine to stop. To

lessen the chance of studs becoming loose, make sure the carburetor nuts

are tight. They should be retightened after the first few taxi

runs, before

the first flight,

and at least once every 20 flight hours thereafter.

Tightening the carburetor nuts can be made much easier if you

modify a 10 mm wrench by making a 45 degree bend in it about 1 1/2

inches from the (open) end. 5.9

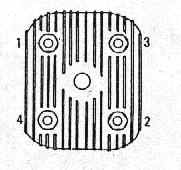

CYLINDER HEAD NUTS As

with any engine, the head nuts on the Rotax recommended that

this be done after taxiing nuts should be tightened in the

sequence shown engine should be

re-torqued after the break-in period. When re-torquing the nuts, they should be torqued to 17 foot-pounds. If a head has been removed, or the nuts are very loose, tighten all the nuts to 5 foot pounds each (using the sequence above), then to 10 foot pounds, then to 17 foot pounds. 5.10

ADDITIONAL AIRFRAME CHECKS Note: In 1982 a completely revised Lazair assembly manual was introduced. For the benefit of those owners having earlier revisions of the manual, some selected paragraphs from the new manual are reprinted below. If you have completed your Lazair, you may wish to check the items listed below, but note that this information is provided as a guide only. If you are satisfied with the way your aircraft riles, it is not necessary to make changes based on these checks, however, you might rind the information useful if you plan to make any other changes. 5.10.1

BALANCE (CENTER -OF- GRAVITY) CHECK Flight

testing has shown that the

Lazair is very tolerant or changes to

the position

or the center-of-gravity.

However, for comfortable

hands -off flying at a reasonable airspeed. and for assurance that there

is no gross error effecting the center-of-gravity, the check outlined

below is recommended with the center-of-gravity positioned as desired,

the Lazair should trim out hands-off at approximately 25 to 28 ~H

indicated airspeed. With the seat positioned

as indicated in the Assembly Instructions, the pilot sits very

near the center-of-gravity, so reasonable differences in pilot

weight do not have an appreciable effect on the position or the

pilot's feet, or even the type or shoes he is wearing. Minor in-night

adjustments to the

position or the centre-of-gravity can be made by just moving the

position or your feet. Also, there will be an effect from the weight or the fuel, so

it is recommended that the following check be made with the

fuel tank approximately half full. With the aircraft on the

ground and the pilot sitting in the seat in the normal (or most comfortable)

seating position, raise the

tail until the boom is level (use a spirit level).

Hold the aircraft in this position with a bathroom scale under

the spreader (T115). The reading

on the scale should be between I and 5 pounds. If the aircraft meets

this requirement it is adequately balanced for the first test fight (If

possible the first fight should be made by an experienced Lazair pilot

who is capable or recognizing any unusual

flight characteristics). Fine

tuning or the balance is best done by flying the aircraft and

adjusting the centre-of-gravity for hands-on trim at the power setting

and airspeed preferred by the pilot.

5.10.2

AILERON DEFLECTION CHECK Move the stick as far as

possible to the right, making sure it is neutral

rore and art. Check that the

aileron deflecti 5.10.3

RUDDERVATOR DEFLECTION CHECK Push

the stick forward as far as possible.

The downward deflection or the ruddervators should be such that

they almost touch each other. Adjust the length or pushrod T18 as

required to achieve the correct downward deflection. Pull

the stick back as far as possible.

The upward deflec 5.11

AILERON BELLCRANK CLEARANCE Please

check the clearance between the 35 bolt holding the EE rod end to your

F39 aileron bellcrank (F39) and the spar cap

(reference drawing C in the parts catalog). Although we have seen

a problem in this area, a worst case tolerance buildup plus a slight

error in locating the bellcrank mount F38 could possibly combine to

cause the bolt to foul on

the spar cap. if necessary the spar cap should be bent slightly to

provide sufficient clearance. 5.12

FUEL TANK STRAP ROUTING When

the large (20 litre) fuel tank was introduced the assembly manual

indicated that the rubber

strap holding the tank in position should be routed over the top or the

tank and beside the large cap. As

most owners have already realized, an extra measure or safety can be

obtained by routing the strap through the handle on the fuel tank before

hooking it onto the T22's. 5.13

FUEL TANK SUPPORT RIVETS We

have had one report of loose rivets on a fuel tank support angle (where

it is riveted to the

T22's), after a series or hard landings. As a minimum, these

rivets should be checked on your walk around, and it is recommended that

they be removed and replaced by stainless steel rivets.

on older models the rivets would be those in FY and F30.

on newer models, (with the 20 litre fuel tank) this would be G62.

on newer models, it is also recommended that the bottom three

rivets attaching the fuel tank saddle, G63, to the seat back, be

replaced by stainless steel as an added precaution. 5.14

NACELLE MOUNTING BOLTS After three years of

production and hundreds or Lazair flying all over the world there was

never a report of nacelle mounting bolts working loose in flight

until last week when

we were told or two such instances.

Fortunately, the

renaming bolts held the engines on the wing but the possibility of an

engine falling off is obviously somewhat disconcerting.

Since the mounting bolts are threaded into nut plates

with an elastic stop nut feature.

The bolts should stay in place unless something degrades the

gripping action or the stopnut. Although the grip can be reduced

slightly with repeated insertion and removal of the bolt. Other factors such as the presence or grease or oil are

probably more significant. To make sure your bolts don't work loose, it is recommended that they be lockwired This may be done by replacing them with drilled-head bolts (type AN3H5A and AN43HA) or by drilling a small hole through the heads for the lockwire.

|

|||||||||||

|

|

|||||||||||

|

|||||||||||

| Ultralight Aircraft News Web Magazine Covering the World of Ultralight Aviation . You may link to these pages or print them out for your own personal use, but no part of this publication may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language, in any form or by any means, electronic, mechanical, manual, or otherwise, without the written permission of Ultralight News. By copying or paraphrasing the intellectual property on this site, you're automatically signing a binding contract and agreeing to be billed $10,000 payable immediately. Copyright Ultralight News | |||||||||||

|

|||||||||||