|

The

recommendations in these updates must be

acted upon before they can be or any benefit.

For your own safety as well as the safety or those around you,

please take the time to make the recommended changes to your aircraft.

In the past six weeks we have had three engines sent

to us for service. Not one or them had the propeller bolts installed as recommended

in update S, item 5.4. Please

read these updates carefully and make the recommended inspections

and/or changes which

apply to your Lazair.

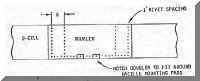

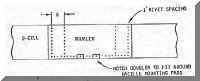

6.1

D-CELL SPLICE

As

you are probably aware, the D-cell skin is comprised of two sections - a

main skin and a tip skin. During

final inspection

of a batch of D-cells

recently. We discovered one which did not have sufficient overlap at the

junction of the main skin and the tip skin to allow the proper edge

distance for the rivets. Although

it is unlikely that

any D-cells were shipped with this defect, please check yours as

described below. Since the outboard end of the main skin is covered by the tip

skin, if the problem does exist, it will

not be obvious and must be checked carefully.

To

check the edge distance for the rivets, it is necessary to know the

position of the outboard edge of the

main skin.

To locate this edge, look at the trailing edge or the bottom or

the D-cell. By looking

inside, you should be able to see the outboard edge or the main skin.

Put a mark on the outside of the

tip skin

at this point and measure the

distance from this mark

to the inboard edge of the main skin (so you know the exact length of

the main skin). Then

transfer this measurement to the leading edge of the D-Cell. You

can now draw a

line on

the tip skin showing

the exact location of the edge of the main skin.

To achieve the correct edge distance, the rivets should be

located so that the centre of the rivet hole is at

least I/4

of an inch from the

edge of the skin. If

necessary, install additional rivets (with the required edge distance)

between the existing rivets.

If

the overlap on your D-cell is insufficient to permit the required

edge distance,

please contact

your dealer or

the factory and w e will make up a special splicing kit for your

D-cell(s) and ship it to you. e will make up a special splicing kit for your

D-cell(s) and ship it to you.

6.2

KEEP YOUR ASI COOL

Although

the Hall brothers airspeed indicators are surviving quite well on

the aircraft,

we have had

two reports of ASI's

becoming so hot that they actually bent slightly and were no longer

useable after being left in the rear window of a car.

6.

CARBURETOR NUTS

In Update 5.8 we reported on a

potential problem of carburetors working loose

and suggested that the nuts be

checked and

retightened periodically.

Since then

we have

determined that the

self-locking nuts work properly. but the studs work loose in the

crankcase. To prevent this from happening, we are now

lock wiring the nuts and

studs after installation of the carburetors at the factory. and it

is recommended that this be done on all Rotax engines.

To install the lockwire. Make sure the nuts are tight. then

drill a

small hole through

each nut (and the end

or the stud). Feed a single

piece or lockwire through both nuts and twist the ends together.

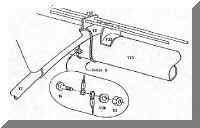

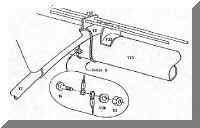

6.4

LARGER FUEL TANK INSTALLATION

Although as stated earlier. we do not

supply a conversion kit for the new 20 Litre (5 U.S.

Gal.) fuel

tank. many owners have

installed the larger tank and now that the new FAA rule specifically

allows a 5 gallon tank. many core owners may wish to make the conversion.

As stated previously. these changes

are not

recommended unless you

have had experience and have access to the equipment required for bending

thin wall aluminum alloy tubing. However.

for anyone who is qualified to do the job. the following guidelines are

provided:

1. To

achieve the proper centre-of-gravity. it is necessary

to move both the fuel

tank and the pilot forward. This

involves rebending and repositioning the seat tube (T44) as shown (or

replacing the T44

with the new T60 seat tube).

2. Make

a saddle for the new tank so that the weight

is carried by the T22's

at the

rear and by

the seat tube at the front. Do

not attempt to support the weight of 5 gallons of gasoline (about

140 pounds at 4 g's) entirely by the T22's.

6.5 RIVETS

IN P3 PLUGS

Although calculations and

testing have shown that one rivet would be sufficient to hold the P3 plugs

into the control

pushrods. we use two

rivets in each to provide a safety factor in the order of ten-to-one for

normal control surface loading. However.

it may be possible in the event of a mishap

(such as

an aircraft being

blown over

by severe

winds while tied down)

to apply stresses beyond the strength of the rivets and shear them off.

If your aircraft is ever involved in any type of incident which

could put abnormal loading on the control

pushrods they

should be inspected very carefully before the next flight. Pushrods

should also be inspected very carefully if you buy a used aircraft -

especially if it has been damaged. if

there is

any indication that a pushrod could have been overstressed. install

an extra rivet in the P3's for security.

6.6

PROTECT YOUR TAPE

All new Lazair's and many older

ones are now being covered in Tedlar.

while the operating life or the

Tedlar is expected to

be many times that

or Mylar

the life or the

adhesives used and the tapes has not been precisely determined.

To obtain the maximum life from

the tapes,

it is

recommended that

all tape

be protected from ultraviolet exposure.

This can be done in several ways.

If you intend to paint your Tedlar then the paint will afford some

ultraviolet protection but the degree of that protection will

depend on the

particular type of pigment

used in the paint. Aluminum

paint works best and it is therefore recommended that the tapes be painted

over with aluminum paint (regardless of whether or not

the balance

of the Tedlar is

painted). As

an alternative, the tapes holding the Tedlar in place may be

covered by a metalized tape (such as type 85O PAU. available from your

local 3M distributor). In

addition to providing ultraviolet protection,

this tape creates a very neat, clean appearance. especially when used over

the foam tape on the ribs.

6.7

ROTAX ENGINES ON .016 INCH D-CELLS

In Update 5, item 5.7 we stated

that the use of Rotax engines on Lazair's with .016 inch

leading edge skins was not recommended.

This statement

was not based on any particular experience, but rather on a lack of

experience. At that time, we

had one demonstrator flying

with this combination,

but we did not

have sufficient time

on it to evaluate the results. Since

then, our demonstrator has continued to perform well. however, one dealer

"who installed Rotax engines on

.016 inch D cell reported that one

of his D-Cells acquired a

slight buckle just inboard of the Nacelle when he shut down the engines

and one of them backfired. Based on this, we are obviously not

recommending the installation of the

larger engines on the

lighter D-cells.

However,

for those "who have already made the

conversion and

those who probably

will (in

spite of our

recommendations), we

suggest that,

as a minimum,

you rivet

on a two root wide doubler of .020 -

2024-T3 aluminum alloy over the leading edge of the D-Cells

under the Nacelles.

suggest that,

as a minimum,

you rivet

on a two root wide doubler of .020 -

2024-T3 aluminum alloy over the leading edge of the D-Cells

under the Nacelles.

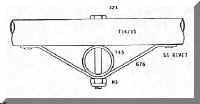

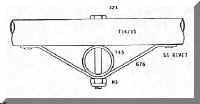

6.8

AXLE GUSSETS FOR RUDDER PEDALS

In the

assembly manual for the rudder pedal kit, there is a reminder that when

one rudder pedal is pushed down, the

other one must come up, and therefore you should not attempt to push on

both pedals simultaneously. However, for whatever reason, people do

occasionally push down on both pedals.

While reasonable pedal

pressure does not cause a problem. excessive force will bend the two 323

bolts which hold the nosewheel axle to the side tubes.

To alleviate this problem, we are now including with

the rudder pedal

kits two small gussets

(G76J to help

support the axle. If

you have an earlier rudder pedal kit and wish to add these gussets, you can make them yourself from two strips of

aluminum alloy .040 to .080 inches thick.

1/2 inch wide and 6 inches long.

Bend and install the gussets as shown.

wish to add these gussets, you can make them yourself from two strips of

aluminum alloy .040 to .080 inches thick.

1/2 inch wide and 6 inches long.

Bend and install the gussets as shown.

6.9

Muffler Outlet Angle

Although

the velocity stacks reduce the amount or oil buildup on the wings

considerably, you may still get a bit

or residue

on the

wings from

the exhaust if you have the new Nacelle mounted mufflers.

This can be greatly reduced by bending the exhaust exit tube in the

muffler upward about 15 degrees. To

do this.

simply fit a 3/4 inch diameter rod or pipe into the exhaust exit

tube and pull it upward to the desired angle.

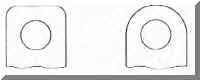

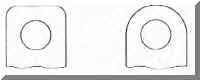

6.10

Front Fitting Radius

A

few kits were shipped recently with front fittings shaped as shown at

left below,

If you assemble

the control system

with the fitting as shown, you will probably rind that it interferes with the pushrod when

you move the control stick to deflect the ailerons.

as shown, you will probably rind that it interferes with the pushrod when

you move the control stick to deflect the ailerons.

To

work properly the fitting should be cut, filed or sanded as shown at right

above.

6.11

PAINT YOUR MYLAR?

If

you recently covered your Lazair in

Mylar and you don't relish the thought

or tearing

it all

off to recover

in Tedlar,

you may be interested in the following:

in spite or the fact that paint will not adhere well to Mylar, a

couple or owners have had relatively good success with it.

The testing which we did a year

ago indicated that

initial adhesion

was extremely poor

after a 48 hour cure. The

same test samples were re-tested about a week ago and while the adhesion

was not as good as we might like. it was acceptable.

If

you wish to experiment with paint on Mylar, we suggest that you let the

Mylar weather

for a couple

or weeks. then degrease it

with Lacquer thinner and paint it with a pigmented urethane (this appears

to be the best or any or the paints we tested). Although the paint should offer

some protection

against ultraviolet

radiation, for

maximum Mylar life it is

recommended that you still follow the guidelines in update 3 item - 3.11.

6.12

RECOIL STARTERS

It's

now almost a year since we started flying with Rotax 185 cc engines,

in general, the

reliability or this

engine has been

very good, but the operating life of the recoil starters has been

less than we would like. The

most common problem we have seen is premature wearing of the starting

pulley (this

is the

cast aluminum device

which mates with the

pawls - not the sheave on

which the rope is wound). The

shape and location or the wear pattern indicates that the pawls are

vibrating in synch with the engine. but vibration

testing with

an amplitude or l0g's

over a frequency range o 10 to 100 Hz. failed to detect any resonances.

Changing the rate or the pawl springs and adding rubber damping seems to

reduce the problem a bit, but not to

an acceptable level.

Evaluating a potential

5olution to this type or a problem Is very time consuming because

although we have had a few starters show signs of wear In the first 20

hours. Most will

last 80 to 100 hours

before exhibiting any indication or a problem. and It can take this

much running time to determine if any improvement has been made.

After

several weeks or changing, testing, and evaluating we have reached the

conclusion that the only way

to get rid of

the problems in the Rotax starter is to get rid of the Rotax

starter. A survey of

manufacturers and small engine mechanics indicated that the most reliable

recoil starter in

common use Is

a relatively cheap and

simple unit made by Tecumseh. We

have several of these starters undergoing testing at present. and so far

the results have been excellent. if

this starter proves to have the reliability we

expect. it

will soon become standard

on all

of our Rotax engines. In

addition to improved reliability. this starter also provides a couple or

other advantages: It has a

larger sheave which makes

it much

easier to pull

when starting the

engine, and the overall size is smaller than the Rotax.

This allows us to use a smaller engine mount which will

accept a close fitting molded engine cowl to reduce drag and improve

the appearance. The

proposed mounting system will use the same rubber mounts and mounting

pattern as we have used since late January 1982 (four mounts on top and

two on the bottom) so retrofitting the new starters should be

relatively easy.

For

those who wish to repair the Rotax starters when necessary. we will be

stocking parts.

For those

who would like

to convert to the new starter. we will make a retrofit kit

available as soon as the test program is complete and the necessary parts

are made. All dealers and

distributors will be notified as soon as

these retrofit kits

are available.

As a service to customers, these kits will be sold at our cost. and

the usual manufacturer and dealer markup will not be applied (when the

kits are purchased to replace Rotax starters).

6.

Engine Mount Angles

We have received two reports of

broken G42 engine mount angles (these are the large brackets which are

bolted directly to

the crankcase).

Although this

represents less than 0.2 of the mounting brackets in use and

therefore does not indicate a trend. a careful inspection of these

brackets should be included in your normal

pre-flight. Since we

will probably be changing to a different type of mount to accommodate the

new recoil starter, we expect to have a few surplus mount angles which we

could supply at no charge to anyone who

returns a broken one.

6.I5

Stabilizer Attachment

Approximately

a year ago we investigated a potential problem of broken F32 pushrod

guides causing the leading

edge of

the stabilizer

to become detached from the boom.

At that time, it was determined that it would be necessary to break

two F32 fittings to cause a problem. and even if this

did happen, the

stabilizer would be

held in position by

the T26 pushrods to permit a

safe emergency

landing. This

conclusion was substantiated by structural testing on the ground. flight

testing. and field reports.

However.

we have since received one report or F32 breakage. believed to be caused

by severe

lateral loading on

the tail

caused by side-slipping

- this was not

possible before the rudder pedals were incorporated). Fortunately. this

did not cause a serious problem and the aircraft made a normal landing,

but it

does renew our

concern. This

situation is not relevant to the newer kits which incorporate the folding

tail because the stabilizer is secured to the boom by the hinge brackets.

However. if you have one of

the earlier

Lazair's and you intend to

execute some of the higher stress maneuvers possible with the rudder pedal

conversion, we suggest the use of a small safety cable wrapped around the

boom and T9 as an added precaution.

However. if you have one of

the earlier

Lazair's and you intend to

execute some of the higher stress maneuvers possible with the rudder pedal

conversion, we suggest the use of a small safety cable wrapped around the

boom and T9 as an added precaution.

6.16

Pushrod Rotation:

If

you have rudder pedals on your Lazair; you may have noticed that if you

push the stick as far as it

will go in one

direction. and push

the rudder pedals as far as possible in the opposite direction, then

reverse both to get full cross control the other way, the BE rodend on one

end of the T18 pushrod will rotate on

its threads about

twenty degrees. Since this

will happen only infrequently in service, the amount of thread-wear In the

P3 will not be appreciable. However.

you should be aware of this situation

and ensure that

the BE which

rotates is threaded into

the P3 at least half an inch. Check

the quality of the threads occasionally and replace the P3 if there is any

indication that the threads are worn.

|