|

The

importance of a thorough pre-flight cannot be over emphasized. You

should follow the factory recommended pre-flight and develop a systematic, habitual approach. Once established,

never vary from your method and of course, always do your own

pre-flight.

Start

at the nose of the craft and during your pre-flight, work around

the Ouicksilver MX in a counter- clockwise manner. If any

questions arise, consult the assembly instructions.

Note:

Checking the "integrity" of a tube means to check for

bends, dents, scratches, etc. Checking the "integrity"

of a wire means to check wire ends for bolt and/or other

fastener security, and to check for twisted or jammed thimbles.

Wires should be free of kinks, frays, abrasions, broken strands,

etc. Wires should be free of sagging, but not so tight that they

"twang" when plucked.

a)

Place

helmet in seat.

b)

Check controls for free and correct

movement.

c)

Check rudder (move stick side-to-side) teleflex cable

integrity and connecting hardware.

d)

Check elevator (fore and aft with stick) and connecting

hardware.

e)

Check spoilers (press pedals) and control line attachments and

pulleys.

f)

Check integrity of seat, lever throttle, seat mount assembly and

attach point hardware.

g)

Check seat support down tube integrity.

h) Check integrity of nose wires.

i)

Check nose tire inflation and integrity of wheel pant.

j)

Check forward integrity of landing gear-nose struts, foot bar,

tension struts and connecting hardware.

k)

Check integrity of triangle bar tubes and attach points including

lower wing wire connections.

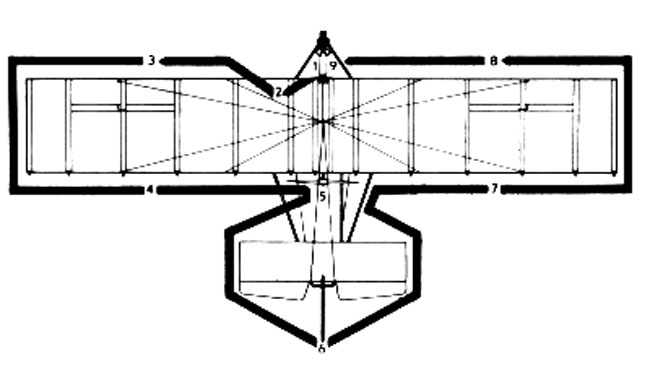

2 a)

Walk under wing and check root tube integrity. Check

all root tube bolts for security including kingpost attachment and

height adjustment.

b)

Check fuel tank mounting security, on-off valve position for 'ON'

and check fuel quantity.

c)

Check all fuel lines, the fuel pump and filter, and carburetor

mount for integrity. Check the fuel tank cross over and if it

contains impurities, drain until contamination is gone. Remember,

water in the gas can cause engine failure!

d)

Check pull starter and all engine components for obvious problems.

Check spark plug caps, all mounting bolts and hardware for

security.

3 a)

Walking to your right, or toward left wing, look and

feel down leading edge spar checking for dents, bends, etc. that may

not be visible because of sail cloth covering.

b)

Check integrity of leading edge wires.

c)

Check spoiler control arm, bungee return, and control line.

d)

Check integrity of compression struts and connectinq

hardware.

4 a)

Walk around left tip and sight and feel down trailing edge

spar. Check integrity of ribs, and make sure they are fully in

position.

b)

Check integrity of trailing edge wires.

5

a) Check

left and right main tire inflation and integrity of wheel pants.

b)

Check axle, axle shaft and axle hardware for integrity.

c)

Check integrity of landing gear down tubes and wires.

d)

Check integrity of reduction unit and condition of belts,

belt tracking and tension.

e)

Check propeller condition (switch off) looking for cracks

or deep nicks. Check prop hub, mounting bolts, and tip

clearance.

f)

Check muffler bracket, shaft coupler and bearings for

security.

g)

Check integrity of tail brace tubes.

h)

Check integrity of tail booms and attach points.

i) Check

that teleflex cable is attached to lower tail wire.

Look

up at kingpost and visually check that all hardware is secure.

6

a) Check horizontal

stabilizer spar and hardware integrity.

b)

Check upper and lower tail wire

integrity.

c)

Check rudder frame tube integrity and check rudder hinge

assemblies carefully.

d)

Check integrity of rudder control cables.

e)

Check elevator frame tube integrity and check elevator hinge

assemblies carefully. elevator push/pull tube and LY of safety

cable.

f)

Check integrity of elevator push/pull tube and hardware and

security of safety cable.

g)

Look up at spoilers and see that they lie flat against the wing

surface.

7

a) Move to right wing and check trailing edge spar and wire

integrity.

b)

Check all compression struts, ribs and spoiler lines for

integrity.

8 a)

Walk around right tip and check leading edge spar and wire

integrity.

9 a)

Check muffler integrity and attach point springs

(safety wired).

b)

Sit in the seat. Adjust and secure shoulder harness/seat

belt.

c)

Buckle your helmet (earplugs are suggested), and connect

parachute "emergency recovery system" to aircraft in

secure manner.

d)

Check airspeed indicator integrity.

e)

Check kill switch integrity.

f)

Actuate all controls several times making sure you can

comfortably reach throttle, control stick, spoiler pedals, pull

starter and kill switch.

NOTE:

This suggested outline for a Pre-Flight Inspection generally

covers the critical areas that MUST be checked prior to each

flight. In addition, EVERY component must be examined after

construction, properly maintained, and correctly stored or

transported to ensure structural integrity and safe flying

characteristics of your Quicksilver MX

|